A sinkhole that formed on Mills Street in Madison in the fall of 2024 called upon the skills and resources of staff from multiple District workgroups to manage. The sinkhole was caused by an offset joint in a 48-inch pipe, circa 1964. With 24-36 inches of wastewater flowing through it, the project team needed to devise a way to stop the flow in order to repair the pipe.

Bypass pumping vs. flow diversion

Installing bypass pumping upstream was one option but diverting flow temporarily to the adjacent Haywood relief sewer was an ideal option. Flow modeling work done by capital planning engineer Jen Hurlebaus helped the team determine if and at what time of day the Haywood relief sewer, a 36-inch PVC pipe, would be able to handle the flow diversion.

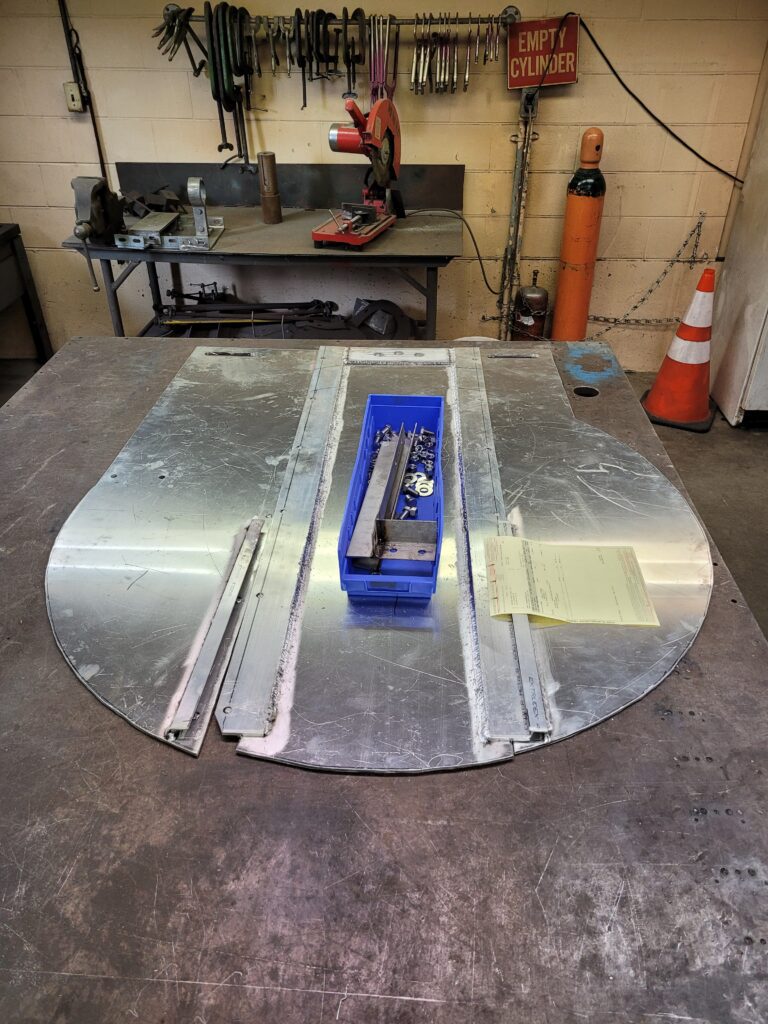

The other key piece in the Haywood relief option was to successfully fabricate and install a stop plate in the pipe to create the diversion at the intersection with the Haywood relief sewer. Mechanic Corey Stark-Prohaska, who has skill and experience in metal fabrication, was able to create a custom aluminum stop plate. “He’s a great machinist and welder,” says Jon Martinson, Corey’s supervisor. “It took quite a bit of time because it had to be just right and it had to be in multiple pieces so it could fit down the manhole and then bolted together once they were down there.”

Testing the stop plate

To be prudent, the team tested the installation of the stop plate and flow diversion to make sure this option would work. During the early morning hours of October 17, 2024, Corey and fellow mechanic Brian Suchomel teamed with Collection System Services (CSS) crew members (and manhole-entering experts) Ray Schneider, Mike Kressin and Kody Wright to facilitate the stop plate installation.

Kody and Corey went down in the pipe to assemble and install the three-piece stop plate while the rest of the team assisted from above. After testing the diversion, the team determined it to be a success, and director of engineering Lisa Coleman worked with CIT Sewer Solutions to see if the pipe diversion would be sufficient to allow them to install a cured-in-place pipe liner to repair the pipe.

After another few weeks of prep and planning, the team returned at 3:00 a.m. on November 12 to conduct the full repair. CSS coordinated with the City of Madison to get the pipe cleaned and clear before the repair, and the team installed the stop plate again. CIT Sewer Solutions was able to successfully install the pipe liner and flow was restored to its normal route.

Brady Lessner, who served as project manager, said the project was a success because of the contributions of everyone involved. Kudos to other key team members not mentioned above: Erik Rehr, Jon Martinson and Todd Gebert.

By Jessica Spiegel