Here’s a fun, historical question for you: When a contractor drilled a large hole in a District force main pipe under Monona Drive in 2009, what temporary fix and innovative repair was used?

- A carved tree limb was pushed into the hole.

- Plastic sheet was melted to the pipe and glued.

- Plywood was placed over the hole, covered with quick-setting concrete.

- None; wastewater was hauled away until a permanent fix was complete.

The discovery

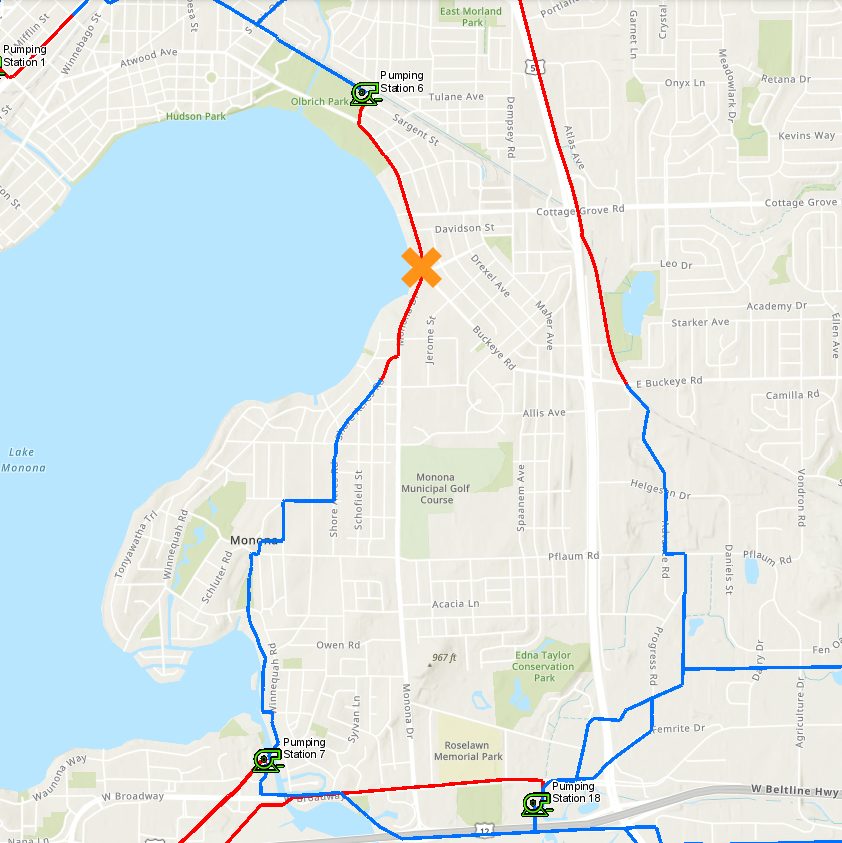

On January 21, 2009, a contractor taking soil borings along Monona Drive vertically drilled a hole into the center of a District force main, which is a pressurized sewer pipe. The force main that was hit pushes wastewater from Pump Station 6 near Olbrich Gardens to a location in Monona where the water can then flow through pipes by gravity to Pump Station 7. When the District team arrived at the intersection of Monona Drive, Lake Edge Street and Buckeye Road, they found an 8-inch hole in the pavement with wastewater running out of it at a rapid rate.

Excavation was done around the pipe to examine the situation and begin repairs. The team found that the hole in the force main was sizable – over 3.5” wide – and round in shape. It was also on a joint, preventing the ability to use wrap-around repair clamps. A piece of replacement pipe would be needed to make the repair, but a pipe with the proper diameter couldn’t be delivered to the Madison area for another week. For the next few hours, until a temporary fix was in place, the team relied on Metrogro haulers to remove material from Pump Station 6 to minimize flooding.

The innovation

Soon after excavating around the damaged pipe and weighing options, innovation struck, and the team decided to try using a block of wood to plug the hole.

Members of the Facilities Maintenance team brought several pieces of wood to the repair site from a tree that had been previously removed from District lagoons. The team cut the limb into a shorter section, carved the wood to fit and then pounded it into the hole manually. The bucket of a contractor’s backhoe was then used for extra force until an industrial-grade tie-down could hold the plug in place. It didn’t leak!

The force main was returned to service, and this innovative repair allowed for continued operation over the next seven days while District staff waited for the repair section of pipe. In the meantime, many members of the Engineering and Operations & Maintenance teams contributed a significant amount of preparation, coordination and activities toward the permanent repair. There was even an element of community outreach to encourage reduced water use during the pipe replacement period.

The result

On January 28, the permanent repairs began. The team brought back Metrogro haulers and City of Madison vactor trucks to prevent any sewer backups in the system that would happen during the shutdown and repair of the force main. Metrogro trucks hauled a total of 36,000 gallons per hour, while the vactors hauled about 15,000 gallons per hour.

It took less than 3 hours – and a lot of background logistics happening simultaneously – to drain the force main to a level that would allow the plug to be removed. The cutting and removal of the damaged concrete pipe, the replacement with the steel repair piece (of the same diameter) and adding the Smith-Blair clamps took just over 3 hours. To finish the job, the entire repair was encased in concrete reinforced with mesh so Monona Drive could be repaved.

In the end, we celebrated some victories and learned a few lessons from this event. We applauded the hard work, collaboration and innovation of our District staff, working under pressure and on short timelines. We received zero reports of basement flooding in the community during the repair.

But, we were also reminded of how fragile our sewer infrastructure can be and of the importance of utility locators before construction, and contracting projects begin. Utility locating services identify the exact placement of sewer lines, preventing damage to our infrastructure and avoiding disruptions to sewer service for the community. Instead of continuing to outsource the service, the District hired two experienced collection system services locators on staff in early 2020.

Thank you to Paul Nehm for compiling the research and the opening question for this article. (If you didn’t guess, the answer to the innovative repair was option A: a tree limb.) To read more about the District and its history, check out the Flow of History series on our blog.