For many wastewater utilities, hauled grease is both a necessary service and an operational headache. Grease trap waste, often referred to as FOG (fats, oils, and grease), must be disposed of somewhere when restaurants and foodservice facilities, such as hospitals or schools, have their traps pumped.

The District has historically accepted hauled grease through its septage program; however, over the past few years, the increasing volume of grease arriving at the treatment plant has created challenges for our staff operating and maintaining the plant.

Accepting hauled grease

The District is required to accept hauled domestic wastewater generated from domestic septic tanks and holding tanks within the service area. Grease trap waste, however, is classified as non-domestic hauled wastewater, meaning acceptance by the District is optional.

Many businesses in the service area generate grease and rely on pumping companies for regular maintenance. Accepting this material provides a valuable service to the community and supports good collection system management by encouraging routine grease trap cleaning. However, to dispose of grease at our facility, haulers must obtain an annual septage hauler permit, which outlines the requirements and conditions for disposal.

Growing challenges

A few years ago, when grease trap waste arrived at the septage site, haulers self-reported the load type and volume. Over time, staff began noticing troubling trends:

- Increasing volumes of grease arriving at the plant

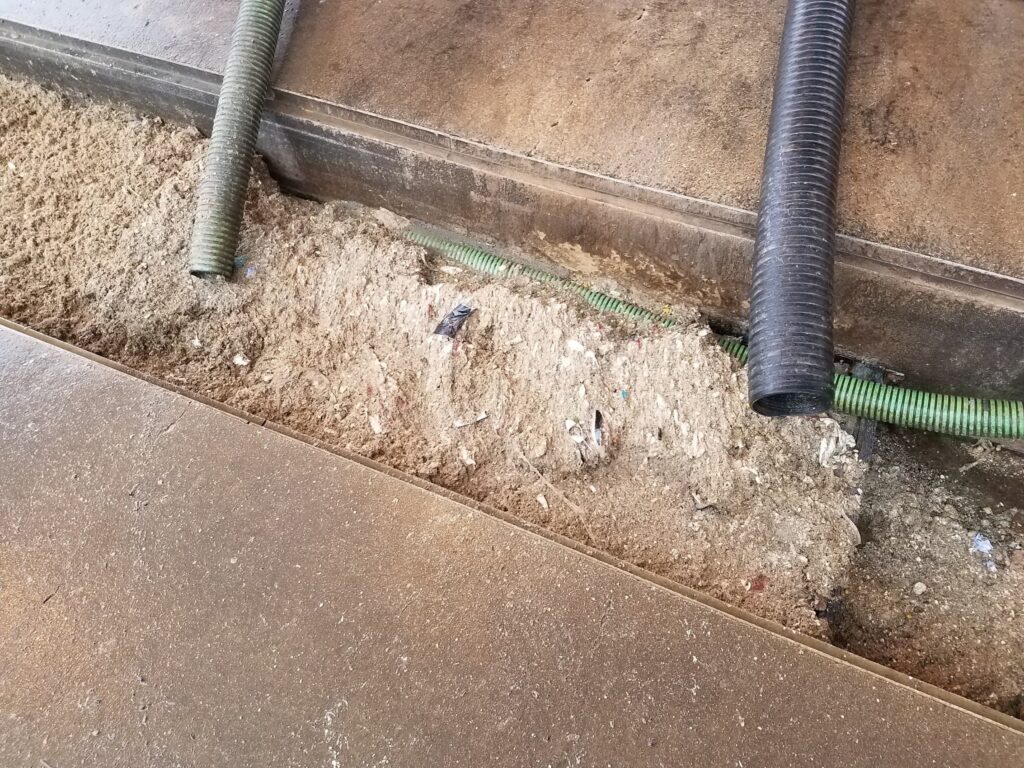

- Loads that weren’t always flowable liquid grease, sometimes causing backups or clogging equipment

- Operational issues such as build-up on thickening equipment and grease accumulation in basins

- Some loads even overwhelmed the receiving trough, requiring additional cleanup and delaying other haulers

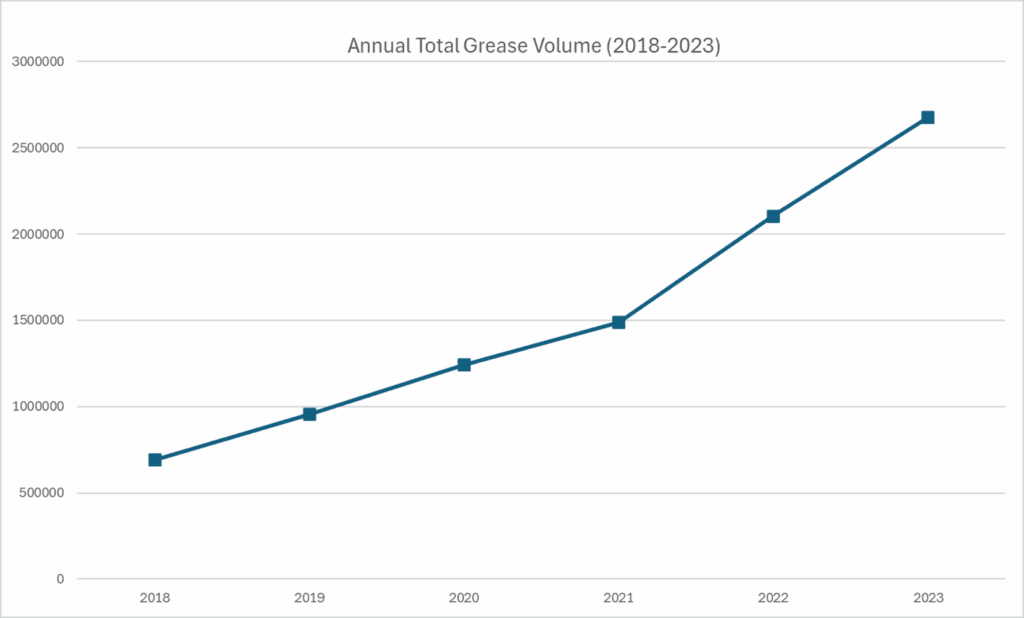

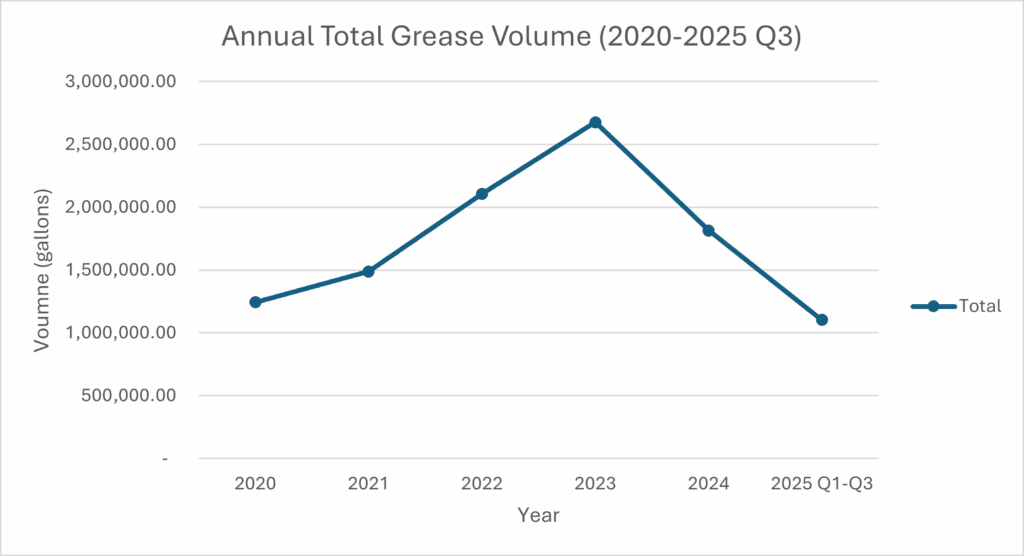

Between 2018 and 2023, we observed an unsustainable trajectory in rising total grease volume, with incoming grease increasing by approximately two million gallons annually over the five-year period.

Closing data gaps

Before recent updates, the grease acceptance program had gaps, and it became clear that the minimal controls were contributing to increasing operational issues, lack of data and expanding grease loads. To make informed decisions, we needed to understand where the grease was coming from, why volumes were increasing so rapidly and how individual haulers were operating.

In 2023, the District began requiring haulers to provide the source address for each load, which improved visibility into the origin of grease. Analysis of the new data revealed that most grease was coming from within or near the service area. We found that a few haulers were responsible for most of the increase, primarily because two large commercial digesters stopped accepting grease trap waste around 2020, dramatically shifting disposal demand toward the District. These insights confirmed that a one-size-fits-all approach to grease hauling would no longer work; haulers had different needs and business realities.

Interim action: Stabilizing volumes

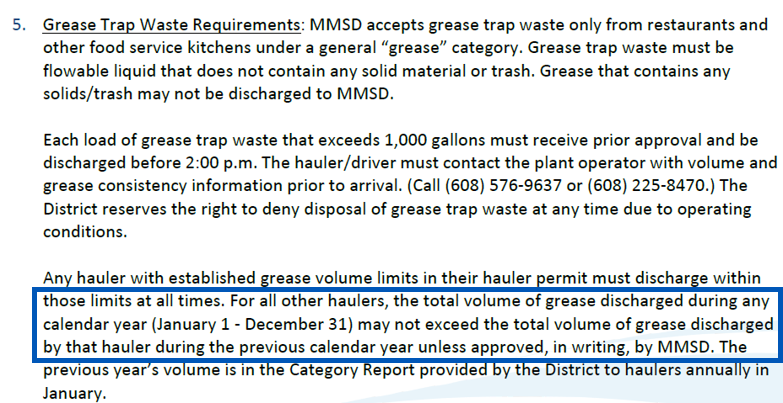

To protect plant operations while longer-term strategies are developed, the District implemented interim grease volume limits. Starting September 1, 2024, the District added an enforceable requirement to its hauler permit that states that no hauler may exceed the previous year’s volume without written District approval.

The goal of this clarification is to reduce operational problems, stabilize grease volumes and prevent sudden, unexpected surges in incoming grease loads. District staff invested significant effort in communicating the change to facilitate cooperation with haulers.

Expanding the focus on hauled waste

In 2025, the District added a Hauled Waste Coordinator position to improve coordination around grease acceptance, along with other typical hauled waste. The goal for this new position is to focus on grease tracking and building stronger relationships with haulers.

Progress has already been made on these fronts, but some haulers are still operating near their allowable limits. We continue to work with these haulers to maintain compliance, recognizing that many haulers share customers or periodically take on new business accounts. We’ve also initiated coordination with haulers that manage large grease trap accounts to minimize scheduling conflicts and enhance operational efficiency. This involves ensuring that haulers do not have overlapping large-volume days and that the District better understands the connections among customers being serviced within the same area.

Although it remains unclear whether the grease acceptance limits implemented in September 2024 fully addressed the root cause of the previous increase, we observed a significant decrease in grease volumes in 2024. This reduction could be attributed to haulers finding alternative disposal outlets or to 2023 being an anomaly—when many businesses resumed regular grease trap service after a period of disruption. Encouragingly, the 2024 total grease volume dropped below 2022 levels, indicating a downward trend. Early 2025 data reinforces this improvement: by the end of the third quarter (Q3), just 57% of the 2025 annual grease acceptance limit had been reached, with only the final quarter remaining.

Long-term grease management

District leadership is committed to a long-term, sustainable strategy that balances service to the community and protection of plant assets. The District is currently evaluating a comprehensive grease management program, including:

- Capacity studies to determine how much grease can be managed without operational disruption

- Improved sampling and analysis of loads

- Continued data tracking on volume, composition, timing, and load sources

- Exploring partnerships with other disposal entities

- Reviewing the grease disposal rate structure

What began as operational frustration has become an opportunity to reshape grease management. Through data gathering, collaboration with haulers and strategic interim controls, the District is laying the groundwork for a solution that preserves plant operations while continuing to serve customers who rely on grease trap disposal.

With thoughtful planning and smart policy, the District is moving toward a future where hauled grease is managed reliably, responsibly and sustainably.

Learn more about the District’s septage hauling program on the For Septage Haulers page.